5 Advantages of Robotic Welding (But 1 Big Disadvantage)

February 22, 2023

Welding robots are nothing new, but the demand for these systems continues to grow.

Why is Robotic Welding More Important Than Ever?

It’s no secret that the welding trade is facing a significant skills shortage. The warning sounded by the American Welding Society found that by 2024, there would be a shortage of 400,000 qualified welders in the industry with older tradespeople retiring. In fact, the average age of a welder is 55, and only 20% of the current workforce is younger than 35.

The reshoring efforts of the American manufacturing industry are also bringing more welding tasks back to the country which is already having a hard time to fulfill demand.

Conversely, the growing manufacturing sector depends on quality welds for all types of industrial and commercial products.

Welding robot applications can help the industry overcome these challenges and add new efficiencies to organizations.

What are the Advantages of Robotic Welding?

When industrial welding robots first appeared, the solutions required significant, upfront investments and were only available to large manufacturers. With the advance of modern technologies, the cost-effectiveness of the solutions became accessible to almost any kind of manufacturing operation.

If you’re wondering whether a welding robot is suitable for your company, here are five advantages to consider.

1. Consistent Welding Workflows

Even experienced professionals get tired and make mistakes. A high-quality weld depends on the consistent execution of each operation across the manufacturing workflow. When welders are overtasked, mistakes creep into the process that requires expensive rework.

Some of the common issues with manual welds include:

- Failure to comply with industry-specific welding codes and standards

- Incomplete penetration of the filler and base material

- Undercutting that weakens the bond between the fused materials

- Slag inclusions in multi-layer welding operations from electrode coating and flux materials

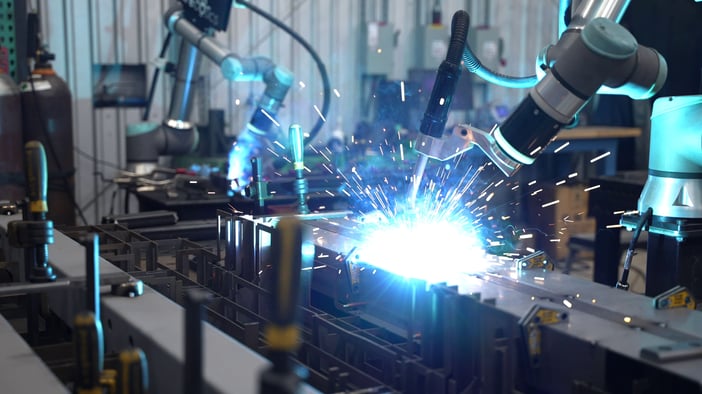

Cobot Welder workflow examples - 2 robots on 1 table vs 1 robot for smaller parts

Cobot Welder workflow examples - 2 robots on 1 table vs 1 robot for smaller parts

By systemizing the welding workflow using cobots, you can set up the entire operations for increased consistency for any welding application.

Since you can set up the welding platform for increased precision, it reduces the number of welding passes required to complete the process while consistently executing each task.

2. Increased Weld Quality and Efficiency

Not only does a robotic welding system speed up your task execution, but it also performs each operation according to your parameters and thereby improves quality. A robotic welder also doesn’t need to take breaks or become fatigued after a long shift.

By accentuating your workforce with a robotic welding system, you can increase your throughput without compromising quality.

Once you’ve set up the system, you can:

- Reduce spattering and save on time spent cleaning each weld

- Increase customer satisfaction by delivering faster on every welding task

- Run operations 24/7 to increase your productivity for increased profitability

- Eliminate repeat tasks that are common when using manual welding

With welds, quality is the primary concern for every company. Welding cobots can ensure quality while speeding up the execution of each task.

3. Conserving Raw Materials

In addition to time savings, a robotic welding platform will also reduce material waste during each operation. As you program the cobot for precision execution, you eliminate mistakes that would require rework and the use of additional materials to correct the weld. When running the welding robot consistently, you reduce the frequency of machine startups that increases your energy consumption.

Robotic welding gives you control over how much material goes into each weld, eliminating variations in cost for each welding task.

4. Reduced Labor Costs

Hiring professional welders can be expensive. Even intermediate-skilled welders are harder to come by, driving up the cost of these resources. A robotic welder may be more costly to acquire in the beginning, but once the platform is up and running, you can consistently execute tasks without the need to hire any additional welders.

With a Hirebotics platform, you empower your existing resources to increase throughput and revenues. With an easy-to-use interface (that doesn’t require any programming), your skilled welders become supervisors that oversee multiple systems and ensure the quality of each welding task.

5. Safer Operations

Welding is a hazardous task that poses many risks to operators. According to the Bureau of Labor Statistics, 28% of all workplace injuries for metal and plastic workers were attributed to welders. A welding robot eliminates many of the risks faced by workers, while safety controls help protect the equipment.

Some of the risks you can eliminate with a robotic welding system include:

- Welder’s Eye caused by the UV light emitted by welding operations

- Occupational diseases like cancer caused by the group 1 carcinogens found in welding materials

- Burns and electrocutions that are common injuries in the welding industry

With workplace safety always a concern in the manufacturing industry, a robot welder will help improve welding safety and avoid costly injuries to your professional welders.

What are the Disadvantages of Robotic Welding?

Although there are many advantages to robotic welding, the system does require a considerable investment. However, once you’ve configured and set up the system, you can recuperate the costs relatively quickly by running the robotic welder non-stop for increased throughput.

Traditional welding robots can be complex to set up and program.

Traditional welding robots can be complex to set up and program.

Another element to consider is the welding robot programming complexity of the system. Many platforms will require you to hire programmers to run the system, increasing expenses.

Welding robot programming complexity is for us a big disadvantage considering the majority of the SMB turning towards automation to solve their challenges.

When looking for a robotic welding platform, you should look for a solution that comes with fast and easy robot programming. This means that your regular workers will be able to learn how to set up and operate the robot quickly, helping you regain the cost of investment faster.

A Cobot Welder from Hirebotics comes with an app interface, making it easier to operate the system and remain in control of every welding operation.

Cobot Welder in Action

Cobot Welder in Action

Increase Weld Consistency and Throughput with Hirebotics

As the demand for quality welds will only increase and new skilled welders are harder to find, Hirebotics can assist your organization with increased throughput using automation. Our systems deliver consistent quality welds and empower your team to increase productivity during every shift.

The Beacon app allows you to set up alerts and always be in control of each cobot, even letting you know if something went wrong and the robotic welder stopped due to an emergency.

To see how our robotic welding systems can help you increase your productivity, get in touch with our team today.