Shipyard Welding Automation ROI for Small and Mid-Sized Fabricators

February 10, 2026

Real numbers for small and mid-size fabricators

DeAngelo Marine needed capacity. They bought a cobot welder for their Gloucester, Massachusetts shipyard.

A single Coast Guard order paid for the entire system.

That order required 200 inches of weld per unit. Manually: 100 minutes per piece. With the cobot: 10 minutes.

One project. Full payback.

Let's talk about whether this math works for your shop.

What it costs

$105,000 gets you:

- Hirebotics collaborative robot

- Beacon platform (included)

- Welding, cutting, or painting system, fixturing, and integration

- Operational system

- 24/7 support

Add-ons:

- Beacon Pro: $200/month for cloud connectivity and advanced features

- Beacon Care: $200/month for additional hardware support and loaner equipment when necessary

- Magswitch Universal Mounting Base: enables magnetic mobility

- Additional accessories as needed

Traditional robotic cells? Significantly more once you add safety caging, dedicated mounting, facility modifications, and integrator fees. But cost is only half the story.

What you get

The cobot maintains consistent speed without fatigue. On repetitive structural welds, it maintains optimal parameters without variation or breaks—no slowdown between morning and afternoon, no difference between Monday and Friday.

Every weld hits the same parameters. Consistent quality, every time.

Your welder supervises but doesn't hold the torch. They can prep the next piece, check quality, handle other tasks, or supervise multiple operations.

The cobot runs second or third shifts with supervision. No overtime premium. No fatigue.

The rework math

You know what rework costs in your shop better than we do.

To calculate it:

- Welds requiring rework per month

- Average cost to cut out and re-weld (labor + materials + schedule impact)

The cobot won't eliminate all rework. Fit-up issues and material problems still happen. But it eliminates rework from inconsistent technique, parameter drift, or welder fatigue.

Through-Arc Seam Tracking follows the actual joint in real-time. Multipass executes the same sequence every time. Parameters don't drift.

If you prevent even a few expensive rework jobs per year, that's real money. Run your numbers.

Why payback happens fast

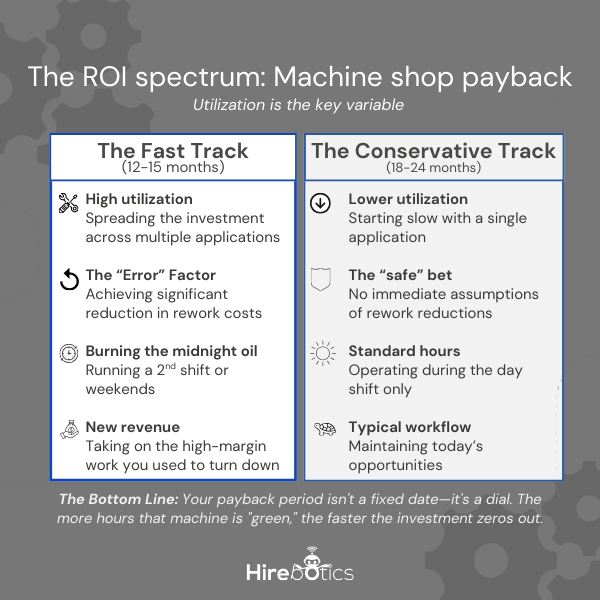

Most shops see payback in 12-24 months.

Faster payback (12-15 months):

- High utilization across multiple applications

- Significant rework reduction

- Extended operations (second shift, weekends)

- Work you were previously turning down

Longer payback (18-24 months):

- Conservative utilization

- Single application initially

- Day shift only

- No rework reduction assumed

The key variable: utilization.

The mobile advantage

Traditional robotic cells sit in one spot doing one job. When that job isn't running, the robot's idle.

Fixed cells in job shop environments run significantly less than mobile systems.

Half or more of your investment sits idle. That kills ROI.

Mobile cobots achieve significantly higher utilization.

The cobot moves between applications. Stiffeners Monday. Bulkheads Tuesday. Frame work Wednesday.

DeAngelo Marine moves theirs between stiffener welding, structural fabrication, and different assemblies as their work demands. They build fishing vessels, government ships, and repair work—rarely the same thing twice in the same spot.

Higher utilization = faster payback. Same investment, more capacity hours, more revenue.

Why Beacon matters to your numbers

Beacon is included. Here's why that affects ROI:

Setup time: minutes to hours, not days. Tap-to-teach programming. Your welder guides the cobot through the path, sets parameters, runs a test. Done. No waiting for integrators.

Every hour in setup is an hour not producing. Beacon minimizes that.

Your welders program it. Interface uses welding terms you already know. Voltage, wire speed, travel speed. No robotics jargon. Your team is running production welds within hours.

Cloud-connected with Beacon Pro ($200/month). Programs backup automatically. Multi-facility shops can transfer procedures between yards instantly. No flying people around for training.

Photos save with programs. Your team photographs the fixture setup and saves it in Beacon. Weeks later, they see exactly how it was configured. Faster setup.

When things break

BeaconCare includes:

- Remote troubleshooting

- Discounts on out-of-warranty repairs and parts

- Loaner equipment for scheduled and unscheduled maintenance

- System health monitoring

Less downtime = higher utilization = better ROI.

When your work changes

Traditional automation dies when work mix changes. The fixed cell does one thing. If that goes away, you're stuck.

Mobile cobots adapt. Your welder adjusts settings and teaches new points. which just takes a few minutes with Beacon.

Compare that to calling an integrator, waiting for availability, paying daily rates, and hoping they can reprogram your traditional robot, or a competitor's cobot.

Flexibility protects your investment.

Financing options

Equipment financing: Most banks finance welding automation. 3-5 year terms are common. Monthly payments are typically manageable relative to capacity generated.

Section 179 deduction: For 2024, deduct up to $1,160,000 in qualifying equipment purchases. Potentially deduct the full cobot cost in year one. Talk to your accountant about timing.

Cash purchase: Eliminates interest. Payback in 12-24 months means you're cash-flow positive relatively quickly.

Your math

What repetitive welding is burying your welders? Stiffeners? Structural welds? Bulkheads? Count the hours per week.

What does that cost you now? Welder hourly rate including burden, times those hours. Add overtime if applicable. Add rework if it's an issue.

What's the cobot capacity worth? Assume conservative utilization to start. Calculate production hours the cobot handles. Extended operations if relevant.

What's the value? Additional capacity for new work? Redeployed welders doing higher-value work? Reduced overtime? Pick what applies to your shop.

Compare to $105K investment. Divide investment by annual value. That's your payback in years.

Factor risk: Lower utilization than expected? Mobile deployment helps. Work mix changes? Beacon reprogramming handles it. Technical issues? Beacon Care provides support.

If the math works conservatively, you've got a decision.

The real question

It's not "can we afford a cobot?"

It's "can we afford not to automate while competitors do?"

Your backlog grows. Your welders are maxed. Lead times stretch. You turn down work. Competitors who automate handle more, deliver faster, win bids you can't accommodate.

That's the cost of not automating. Harder to quantify, but real.

Bottom line

$105,000. Payback typically 12-24 months. Key variable is utilization—mobile deployment drives this significantly higher than fixed cells.

DeAngelo Marine covered their investment with one Coast Guard project. Your payback might come from capacity increase, rework reduction, extended operations, or backlog relief.

Run your numbers. Be conservative. If it still works, you know what to do.

Want to calculate ROI for your specific operation? We can walk through your applications and costs to model realistic payback for your facility.