Robotic Welding Fixtures: Design Tips and Best Practices

April 6, 2022

Today, remaining cost-competitive in the fabrication and manufacturing industry is still a challenge for SMBs. Compounding the issue is the scarcity of professional welders available in the industry, leaving many high-mix, small-volume manufacturers struggling to maintain the required throughput in their operations.

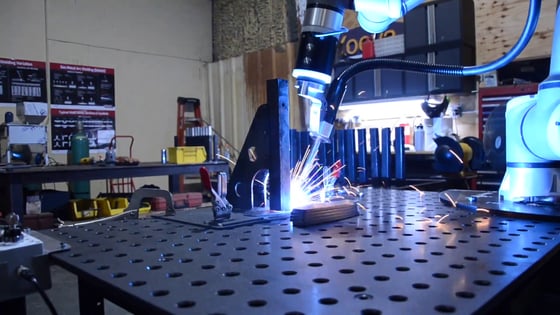

For SMEs leveraging robotic welding systems or welding cobots to maximize productivity, the design of robotic welding fixtures should also receive due consideration.

While human welders can easily adjust to part variations and subtle differences in seam position, the same doesn’t hold for robotic welding systems. Manual vs. robotic fixture designs need to accommodate these differences in workflows.

Below, we look at the challenges and best practices when designing robotic welding fixtures.

Challenges with Designing Robotic Welding Fixtures

When it comes to high-mix, low-volume welding projects, the job’s profitability requires you to optimize every step of the workflow. Welding fixture designs need to be as simple as possible while ensuring the required repeatability and consistency that makes a one-time-through weld operation possible, especially when not relying on human welders.

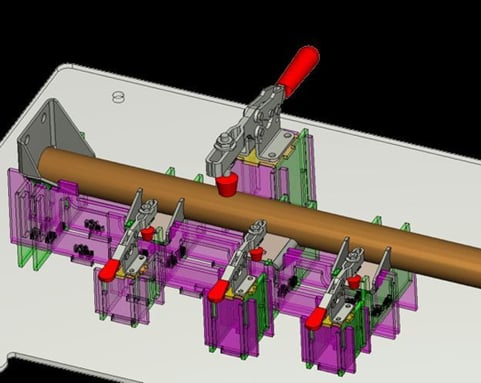

Example of welding fixture designed in Nucleo

Example of welding fixture designed in Nucleo

Some of the significant challenges that your approach to fixture design needs to address include:

- Maintaining the highest level of consistency and repeatability for each workpiece

- Reducing the time and cost of the weld operation while ensuring operator safety

- Supporting all the orientation and manipulation tasks of the part for multiple-step weld workflows

- Accommodating the required lead times to deliver the job on time without any quality issues

An optimized robotic fixture design will ensure speed, quality, and affordability for each part that goes through the welding workflow. Every workpiece needs to be set up precisely and securely while ensuring dimensional accuracy that prevents the distortion of the final product.

Best Practices for Designing Robotic Welding Fixtures

While fabricators may want to introduce sensing and vision systems that help a robotic welder locate the seam position of the workpiece, this adds complexity to the weld cell.

With increased complexity, you introduce additional challenges like having access to skilled resources with the requisite programming skills, leading to increased costs and longer cycle times for each weld.

Resources will need additional training, and if they leave the organization, you’ll be back to square one. These resources are also expensive and hard to come by, making it less feasible than improving your robotic welding fixture designs.

Let’s look at some of the best practices and design tips for designing robotic welding fixtures.

1. Design the Fixture for Repeatability and Consistency

Robot welders, even those that are easy to program like the Cobot Welder from Hirebotics, will move along a consistent, repeatable weld path. The fixture will need to be precise according to these tolerances to perform consistently on each workpiece.

Typically, the position tolerance for each weld joint needs to be within half the diameter of the welding wire. If the robot uses a 0.045” weld wire, the weld joint must be within approximately 0.020” when fixtured to the welding table.

2. Consider the TCP and Reach of the Robot

Considering the welding torch setup, the fixture design should accommodate the true tool center point (TCP). The welding robot will need to reach every weld joint without running into obstructions that could offset the TCP or damage the neck of the weld gun.

In some instances, you may need to use a rotisserie table to reach every weld joint during operation. Designing the fixture with a CAD simulation will help ensure you can reach all the welds without running into obstructions.

By accurately designing the fixture according to the true TCP of the weld gun, you can maintain the required consistency and repeatability while avoiding quality issues such as excessive spatter or missed welds during the workflow.

3. Optimize the Fixture for Loading and Unloading

To make the most of the fixture and maintain the required throughput for increased profitability, the fixture should allow for easy loading and unloading of each workpiece. The faster you can unload the welded assembly and load a new workpiece, the shorter the cycle time and the higher your production rate will be.

Another trend that is shaping the robotic welding industry is incorporating material handling robots for holding workpieces in the weld cell. With this approach, the other robot will hold and present the workpiece to the robotic welding system according to the programmed parameters. Although, remember that this will increase the cost and complexity of the operation once again.

4. Use Fixture-as-a-Service to Simplify Welding Fixture Design

The design process of a welding fixture can need considerable time and expertise according to the complexity of the assembly. With the current labor shortage, SMEs may not always have the bandwidth to design their own fixture efficiently. Fixture-as-a-Service (FaaS) like offered by Camtek Optisolutions is a great way to optimize complex fixture designs for robotic welding applications.

For SMEs that need to accommodate high-mix, small volume run, FaaS helps address the challenges of designing complex fixtures and helps overcome staffing shortages for fabricators. This approach leverages the experience of professionals in fixture design and provides cost-effectiveness.

With FaaS, fabricators can:

- Facilitate quicker changes between weld operations for different workpieces

- Quickly cost and forecast weld projects with accurate pricing for fixtures and cycle times

- Save time and costs on fixture design using CAD and CAM solutions to source new fixtures quickly

At Hirebotics, we often recommend customers use FaaS from Camtek due to their ability to design complex robotic welding fixtures while maintaining tight tolerances and reducing lead times. They use a proprietary software solution to generate the geometry of the fixture and provide you with detailed CAD models that you can manufacture yourself or order from a local machine shop.

Listen to first-hand experience from Ricky Rater, owner of Pearson Livestock Equipment

To optimize your just-in-time (JIT) manufacturing and fabrication workflows, FaaS remains a viable option to maximize profits and decrease cycle times.

You can discuss your needs with Camtek by contacting them here.

Optimize High-Mix Small Volume Weld Projects with Hirebotics

Hirebotics provides a robotic welding system that incorporates the latest cobot technologies for increased throughput and productivity.

Combined with FaaS solutions for fixturing, SMEs can achieve a price point that is affordable to the customer and profitable for the company. With an easy-to-train cobot and modular robot welding fixture design, you can optimize your entire welding workflow without compromising quality.

To discuss our cobot welding system with an expert, get in touch with Hirebotics today!