Mobile Welding Automation for Shipyards: Why Fixed Robotic Cells Fail

January 15, 2026

Walk into any shipyard and you’ll see the core challenge with traditional welding robots immediately: the work never stays in one place.

This week, you’re welding deck panels in Bay 3. Next week, it’s bulkhead assembly. The week after, you’re running stiffeners on a completely different fixture. Welders move between stations. Fixtures get reconfigured. Schedules shift when a vessel owner needs something rushed.

Now imagine installing a traditional robotic welding cell.

It requires a concrete pad, safety caging, and dedicated floor space. It stays in one spot—permanently.

If the robot can’t move with the work, it sits idle while your welders hustle across the yard.

That’s why most shipyards still rely heavily on manual welding. Not because they’re anti-automation—but because fixed automation doesn’t match how ship fabrication actually works.

Shipbuilding is not an assembly line

Even shipyards building similar vessel types face constant variability:

-

Stiffener welding happens across multiple fixtures

-

Bulkhead assemblies move between stations based on size and availability

-

Frame fabrication shifts bays as priorities change

-

Large assemblies occupy space for weeks—then the bay gets repurposed

Shipyards operate like job shops where the “jobs” weigh tons and consume half the facility.

One Northeast shipbuilder working on fishing vessels, government ships, and repair work rarely builds the same structure twice in the same location. For them, traditional robotic welding cells never penciled out—the investment would sit idle while skilled welders stayed overloaded.

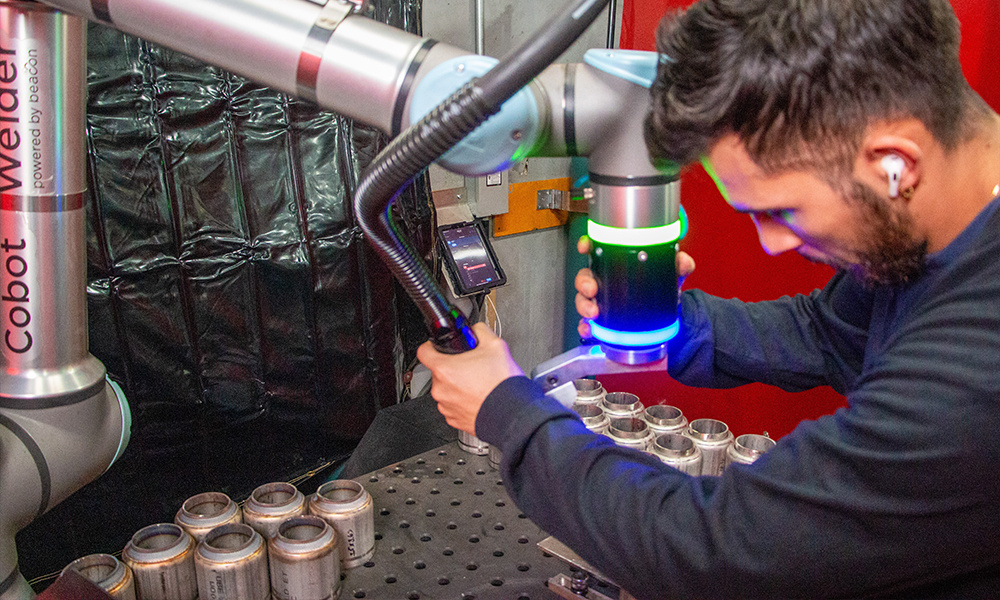

What mobile welding automation actually means

Mobile welding automation isn’t just a robot on wheels. It’s a system designed to move between jobs without sacrificing precision, safety, or repeatability.

A magnetic mounting base allows a collaborative welding robot (cobot) to attach directly to steel surfaces—tables, fixtures, frames, or structural components—without bolts or permanent modifications.

Setup takes minutes, not hours.

When the job finishes, the cobot is released, moved to the next station, mounted again, and back in production—often the same shift.

For shipyards, this means:

-

No concrete pads

-

No permanent safety cages in most applications

-

No facility modifications

-

No idle automation waiting for the “right” job

One welding cobot, multiple shipyard jobs

Here’s how mobile automation works on a real shipyard floor:

Morning: The cobot runs repetitive stiffener welds on deck panels—consistent fillet welds, taught once by an experienced welder.

Midday: That work finishes. The cobot is relocated to a bulkhead fixture in another bay. New paths are taught. Production resumes.

Afternoon: Structural frame welds take priority. The same cobot moves again.

Same robot. Multiple applications. Maximum utilization.

Fixed robotic cells can’t do this. When the work moves, they sit empty.

The utilization problem with fixed robotic welding cells

In high-volume automotive plants, industrial robots may achieve 60–70% utilization.

In shipbuilding environments, utilization often drops dramatically because:

-

The robot is optimized for one job

-

Most welding happens elsewhere in the yard

-

Schedules and bays change daily

That’s a six-figure investment producing value only part of the time.

Mobile welding automation flips the equation. Instead of building monuments to one application, shipyards deploy welding capacity wherever the work is happening.

As volume grows, adding capacity doesn’t require more concrete, fencing, or facility redesign—just another mobile unit.

Why overhead and gantry systems rarely fit job-shop shipyards

Some shipyards experiment with overhead rails, gantries, or suspended robotic systems. While effective in limited scenarios, they introduce new challenges:

-

Facility modifications and structural engineering

-

Rigging and setup time to reposition equipment

-

Safety complexity around suspended loads

-

Reduced flexibility when schedules change

Magnetic mounting avoids these tradeoffs. The cobot mounts directly to the work surface, providing stability for production welding—including multipass applications—when used within rated limits.

Built for real shipyard welding conditions

Ship fabrication isn’t clean or perfectly repeatable:

-

Fit-up varies

-

Plate thickness is substantial

-

Welds are long and structural

-

Assemblies aren’t always square

Hirebotics’ Beacon platform is designed for these realities.

Through-arc seam tracking

Beacon’s seam tracking uses real-time electrical feedback from the welding arc to follow the actual joint—not a fixed, idealized path. When stiffeners or plates vary slightly, the cobot automatically corrects position during the weld.

Multipass welding

For thick plate and structural joints, Beacon’s multipass capabilities break complex welds into individual, verifiable passes. Each pass can be adjusted, tested, and confirmed before moving on—no need to reprogram entire sequences.

Mobility combined with adaptive welding means shipyards don’t have to choose between flexibility and quality.

What implementation really looks like

Mobile welding automation doesn’t require months of setup.

-

Identify repetitive structural welding—stiffeners, bulkheads, frames, subassemblies

-

Mount the cobot to existing steel fixtures or tables

-

Welders teach paths using Beacon’s welder-first programming

-

The cobot moves with the work as jobs shift

No robotics specialists. No waiting on engineers. The knowledge stays with your welding team.

Scaling capacity without scaling infrastructure

Fixed automation creates an all-or-nothing decision: justify a dedicated cell or don’t automate at all.

Mobile cobots scale incrementally:

-

Start with one unit on your highest-volume work

-

Add capacity as demand grows

-

Deploy additional cobots across shifts or facilities

For organizations with multiple yards, Beacon’s cloud-connected platform allows programs to transfer between locations—keeping procedures consistent without constant travel or retraining.

This isn’t about replacing welders

Shipbuilding faces a persistent welder shortage. Automation isn’t about replacement—it’s about multiplication.

Mobile welding automation frees experienced welders from repetitive production work so they can:

-

Tackle complex joints

-

Supervise quality

-

Train apprentices

-

Support urgent projects

The cobot continues producing what it’s been taught while skilled welders apply their expertise where it matters most.

The bottom line

If your shipyard handles repetitive structural welding, stiffeners, or bulkhead fabrication, automation can help—but only if it fits how your work actually moves.

Fixed robotic welding cells struggle in dynamic shipyard environments. Mobile collaborative welding automation—using magnetic mounting, welder-taught programming, and adaptive features like seam tracking and multipass—matches the reality of ship fabrication.

Shipyards don’t need more permanent installations. They need welding capacity that moves with the work.

Want to see how mobile welding automation would work in your shipyard? Let’s talk about adapting Beacon-powered cobots to your specific operations.