Automating Shipbuilding Without Rebuilding Your Shop

January 19, 2026

Automating welding in shipyards has traditionally meant expensive facility modifications, fixed robotic cells, and months of disruption. Concrete pads. Safety caging. Dedicated floor space. And when it’s all done, you’re left with a robot that can’t move.

But modern collaborative welding automation doesn’t work that way anymore.

Today, shipyards can deploy mobile welding robots that work with existing tables, fixtures, and floor space—without rebuilding their shop.

Why most shipyards avoid welding automation

Most shipyards avoid welding automation for one simple reason: they think it means tearing up their facility.

Concrete pads. Safety caging. Dedicated cells. Electrical work. Months of disruption. And when it’s all done, you’ve got a robot that can’t move and half your shop floor tied up in permanent installations.

No wonder many yards stay with manual welding—not because automation wouldn’t help, but because traditional robotic welding doesn’t fit how shipbuilding actually works.

Your shipyard already works—Automation should fit it

Your current setup already handles the work.

You’ve got steel tables, welding fixtures, and assembly stations. Your welders move between them as jobs demand. Your floor space flexes with your production schedule.

That setup doesn’t need to change.

Hirebotics’ collaborative welding cobots work with what you already have. Those steel tables your welders use? Ideal mounting surfaces. The fixtures you built for manual welding? They work for automated welding too. The floor space you need to keep flexible? It stays flexible.

No facility modifications.

No permanent installations.

No rebuilding your shop to accommodate automation.

Magnetic mounting makes mobile welding automation possible

Traditional industrial robots bolt to concrete pads or welded mounting plates. Once installed, they’re stuck. Moving them means another installation project—more concrete, more downtime, more cost.

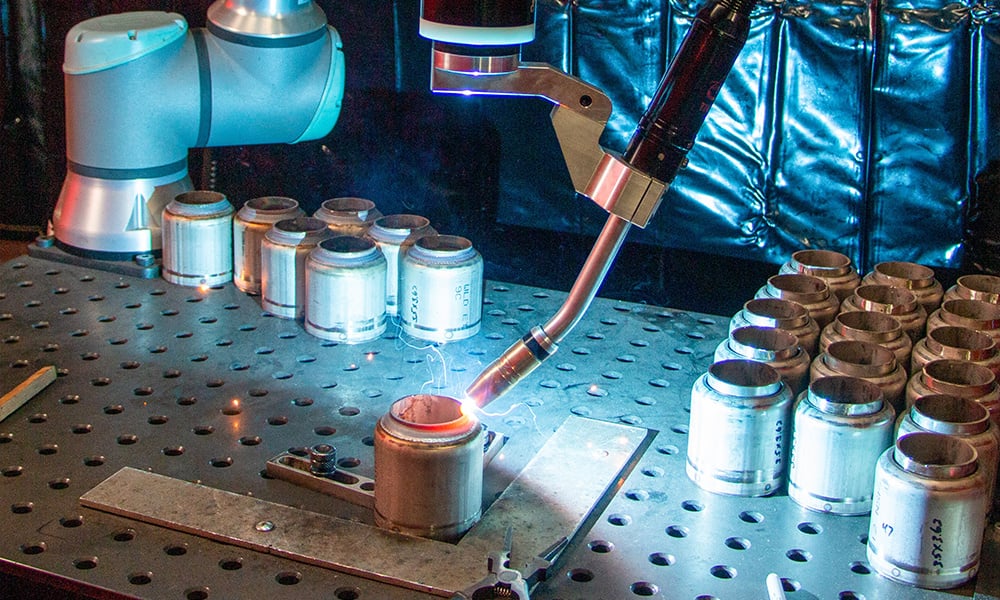

The Magswitch Universal Mounting Base works differently.

It’s a magnetic mounting system that securely holds a collaborative welding robot to any steel or cast-iron surface—tables, fixtures, frames, or workstations.

Setup time: minutes.

Your welder positions the cobot where the work is, engages the magnetic base, and starts welding. The hold is strong enough for production welding, including multipass welds on thick plate. When the job moves, release the magnet and reposition the cobot.

No tools.

No facility work.

No permanent changes.

Real-world example: DeAngelo Marine

DeAngelo Marine in Gloucester, Massachusetts uses this exact approach. They build fishing vessels, government ships, and repair work on the same shop floor.

Their cobot moves between stiffener fixtures, structural assemblies, and different workstations as jobs require. The magnetic base mounts to their existing steel tables—no modifications needed.

What “no facility modifications” actually means

Let’s be specific about what you don’t need to do.

No concrete work

-

No pads poured

-

No anchor bolts

-

No curing time

-

No floor disruption

No electrical infrastructure

-

Runs on standard 110V or 220V outlets

-

Same power your welders already use

-

No special panels or circuits

No traditional safety caging

-

Collaborative robots work alongside welders

-

No barriers consuming floor space

-

No light curtains or interlocks for typical applications

No fixture modifications

-

Existing welding fixtures work as-is

-

Magnetic base mounts to steel tables or frames

-

No drilling, welding, or permanent attachments

No facility engineering

-

No structural analysis

-

No permits or inspections

-

No facility downtime

This matters more than it sounds. Many shipyards delay automation for years because they can’t afford facility work, can’t spare the downtime, or can’t dedicate floor space to permanent cells.

Remove those barriers, and automation becomes realistic.

Your first collaborative welding robot: Zero infrastructure

Here’s what implementation actually looks like:

Week 1: Identify high-volume repetitive welding—stiffeners, structural welds, or subassemblies. Confirm steel tables or fixtures are available (they are).

Week 2: The cobot arrives. It plugs into an existing outlet.

Week 3: Your welders program it using Beacon’s welder-taught interface. They demonstrate weld paths. The cobot repeats them. Minor adjustments. Production begins.

No installation project.

No construction timeline.

No disruption.

Working with the fixtures you already own

Most shipyards have years of investment tied up in custom welding fixtures. They’re built for specific assemblies, orientations, and workflows.

Traditional automation often forces you to abandon that investment—new fixtures, new layouts, new workflows.

Mobile collaborative welding automation preserves it.

That stiffener fixture from five years ago? Use it.

That bulkhead jig holding assemblies at the perfect angle? Keep it.

That custom frame for structural work? Same setup.

The cobot mounts where a welder would stand and follows the same paths—only now it repeats them with consistency.

Scaling shipyard welding automation without infrastructure

With fixed automation, scaling means more infrastructure. Every robot needs its own permanent cell.

With mobile automation, scaling means adding cobots—nothing else.

Your second cobot runs on different fixtures. Your third doubles capacity during peak periods or covers additional shifts. None of them require permanent floor space.

You’re scaling welding capacity, not infrastructure.

The floor space problem with fixed robotic welding cells

Floor space is critical in shipbuilding.

A traditional robotic welding cell with safety caging can consume 200+ square feet permanently—even when idle.

Mobile, collaborative cobots consume zero permanent floor space. When they’re working, they’re mounted to the job. When they’re not, they sit on a cart.

Your floor stays flexible. Your shop stays productive.

Built for real shipyard conditions

Ship fabrication isn’t clean or perfect. Fit-up varies. Plate is thick. Assemblies aren’t square.

Beacon’s platform is designed for this reality:

-

Through-Arc Seam Tracking adapts to fit-up variation in real time

-

Multipass welding tools break heavy welds into verified, repeatable passes

Mobility plus real-world welding capability means you don’t choose between flexibility and quality—you get both.

Starting small, growing smart

Most shipyards start with one cobot on high-volume repetitive work—often stiffeners or structural welding.

That first cobot generates ROI and builds confidence. The second expands coverage. The third scales shifts or facilities.

Each step adds capacity without locking you into infrastructure decisions you can’t undo.

The bottom line

Shipyards need automation—but not at the cost of rebuilding their facilities.

Collaborative welding cobots with magnetic mounting work with:

-

Your tables

-

Your fixtures

-

Your floor space

-

Your workflow

No concrete.

No caging.

No permanent installations.

No facility downtime.

Just welding capacity that goes where the work is.

If you’ve delayed automation because you couldn’t afford the disruption, the floor space, or the infrastructure—those barriers are gone.

The question isn’t whether you can afford to automate.

It’s whether you can afford not to.