Beacon vs Teach Pendant: Next Generation of Fabrication Automation

February 12, 2024

Collaborative robots (cobots) have become pivotal in enhancing productivity and efficiency in the welding and manufacturing sectors. They allow us to consistently produce quality, repeatable parts while saving on manpower and consumables.

How can we use these machines to their full potential when it takes weeks to train welders to use them properly?

The key lies in programming and control - typically managed by a teach pendant. As owners seek more streamlined and user-friendly solutions, an important question needs to be asked: Is the traditional teach pendant still the best tool for the job, or is there a more innovative approach?

In this article lets discuss:

- Complicated Traditional Teach Pendants

- Hirebotics Beacon App: The Smarter Choice

- Key Advantages of Beacon - How Easy Is It To Weld With Beacon?

- Easy Transfer and Sharing of Programming - Beacon Care - Comprehensive Support for Your Cobot

- The Impact on Welding Automation

- A Teach Pendant vs Beacon Comparison

- Beacon: Easy to Implement and Scale

Complicated Traditional Teach Pendants?

Teach pendants, the traditional tools for robotic control, have evolved over the years, especially with the advent of cobots. These devices have varied in shape and size, reflecting the changing needs of industrial robotics.

Initially, traditional robots were programmed via code entered through their teach pendants, requiring a deep understanding of the specific programming language tied to each robot brand. This requirement often posed a significant challenge for many weld shop owners.

With the entry of cobots into the market, there was a shift towards more user-friendly teach pendants. These new pendants featured simplified graphical interfaces, making the programming process more intuitive. Some OEMs even developed specialized "apps" for cobots allowing 3rd party development like Universal Robots and their UR plus platform.

Despite these advancements, challenges remain with teach pendant approaches:

- Complexity: Even with graphical interfaces, using these pendants requires specialized training and a good grasp of robotic logic and programming. This complexity remains a daunting barrier for many weld shop owners.

- Cost and time: The cost and time investments required for staff training or hiring skilled programmers pose significant barriers to entry for small to medium-sized shops.

- Operational rigidity: Making changes or adjustments in programming still demands expertise. This lack of flexibility can be a drawback in dynamic manufacturing environments where quick adaptations are essential.

- Limited mobility: Operators are typically bound to the robot’s location due to the physical nature of teach pendants, which can be cumbersome in large or complex setups. This constraint can lead to inefficiencies and increased downtime, particularly when managing multiple robots.

While teach pendants are still commonly used in robotic automation, their inherent complexity, the need for specialized programming knowledge, and operational limitations still present significant challenges.

It can still be challenging for smaller businesses to efficiently integrate cobots into their operations.

So what is the solution?

| Key Takeaway The Beacon App offers an intuitive, user-friendly alternative to traditional teach pendants. It simplifies robotic programming and empowers shop owners, especially in welding industries, to integrate automation into their operations. |

Hirebotics Beacon App: The Smarter Alternative

![]()

If there was a more straightforward way to handle cobot programming, wouldn't you want to know about it?

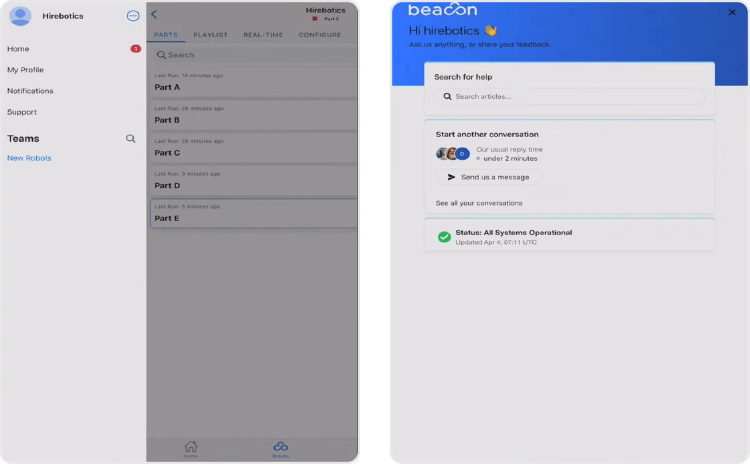

The Beacon app by Hirebotics is changing robotic programming as we know it. By introducing a phone or tablet app-based approach to cobot programming, Beacon is breaking down these longstanding barriers, offering a more accessible, flexible, and user-friendly alternative to traditional teach pendants.

But isn't programming language hard to understand?

With Beacon, pre-defined welding terms that are easy to understand make it simple for any welder to use even if they don’t have any programming knowledge. Let's take a closer look at what makes Beacon a game-changer for cobots.

Beacon breaks away from the traditional teach pendant method, offering an interface anyone can learn and use in minutes!

Key Advantages of Beacon

- Ease of use: Beacon simplifies programming cobots for welding tasks with an intuitive smartphone app, empowering even those without prior robotic knowledge.

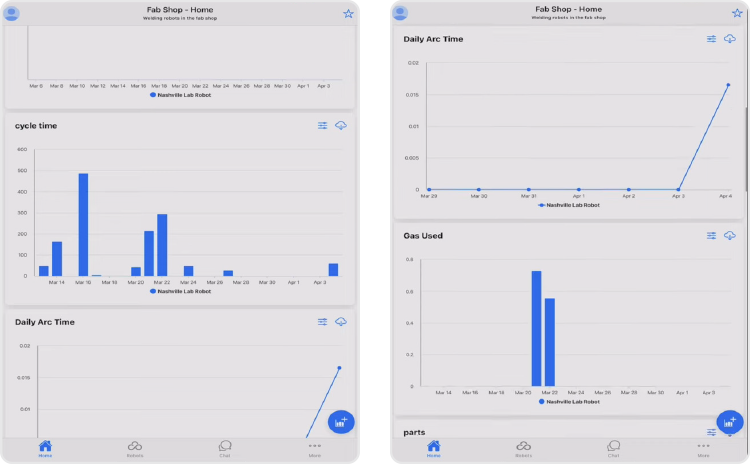

- Real-time monitoring and alerts: The software allows real-time monitoring of cobots and sends alerts when system errors or stops occur, enhancing operational efficiency and reducing downtime.

- Flexibility and scalability: Beacon supports multiple users and teams, allowing businesses to scale their operations by adding more cobots and users as needed.

- Cost-effective solution: No need to hire programmers or additional welders that understand robotics.

How Easy Is It To Weld With Beacon?

For shop owners looking to simplify welding automation in their operations, Hirebotics' Beacon app offers a refreshing change from the complexities of traditional teach pendants.

Beacon simplifies the programming process, using easy-to-understand welding terms that any welder can grasp, regardless of their technical background. This approach ensures that transitioning to robotic welding is a smooth and straightforward experience, enhancing the efficiency of your shop's operations.

Experience the refreshing, easy-to-use way to teach your cobot with Hirebotics’ Beacon app that takes only minutes to learn:

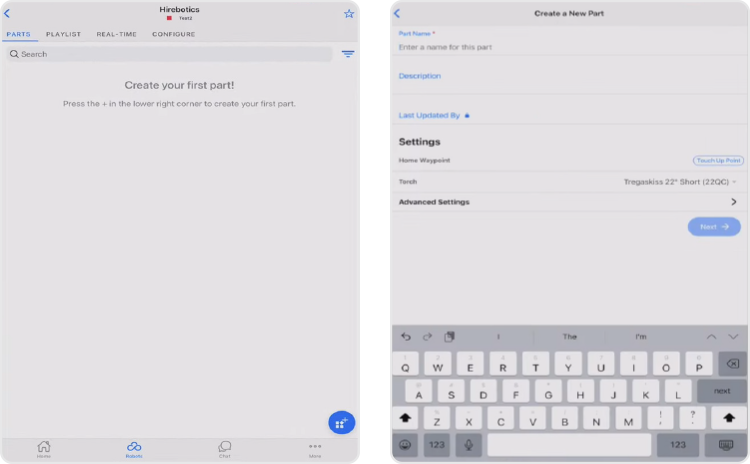

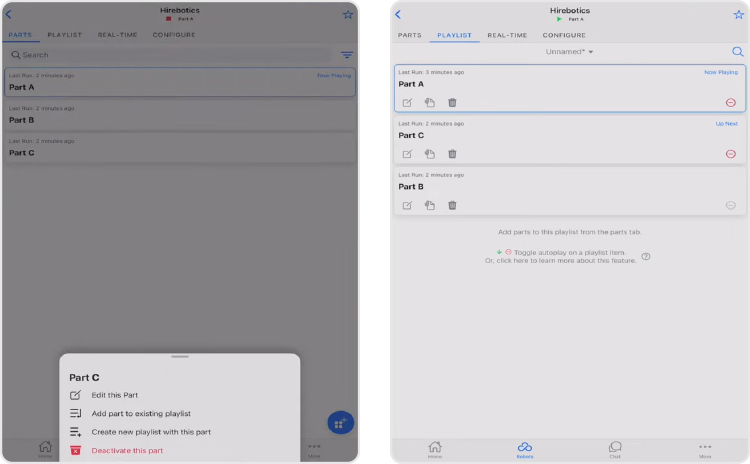

1. Create a Part: Begin by setting up your part in the Beacon app.

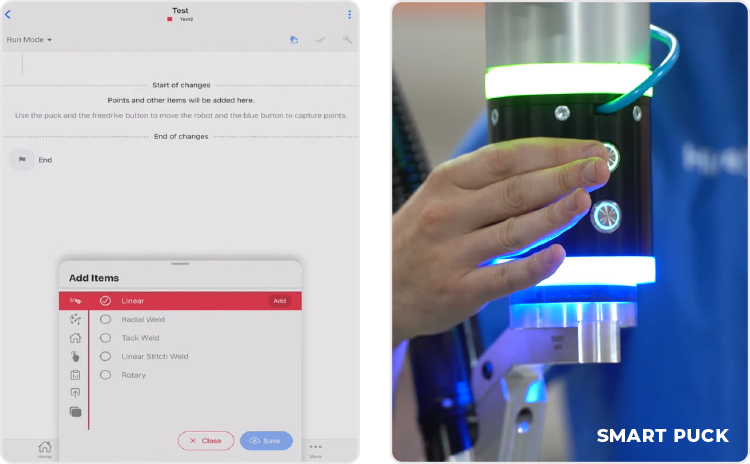

2. Teach Weld Types: Learn to program various welds like linear, radial, and stitch welds using the smart puck.

3. Set Tack Welds: Implement tack welds for your project.

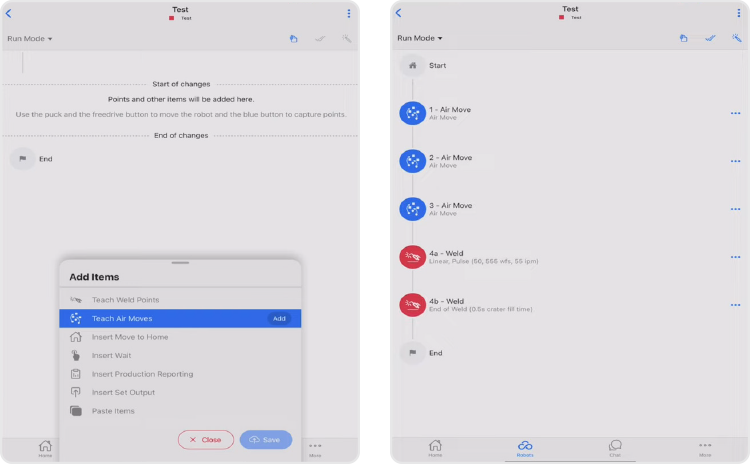

4. Add Air Moves: Introduce air moves to navigate around obstructions.

5. Create Playlists: Organize different welding sequences into playlists for easy access.

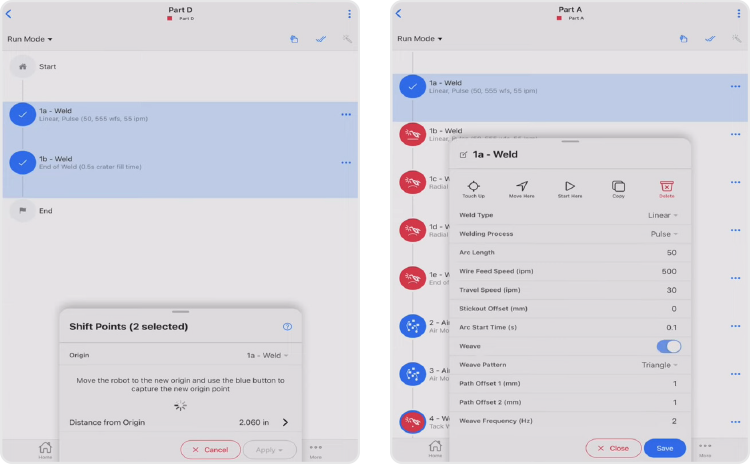

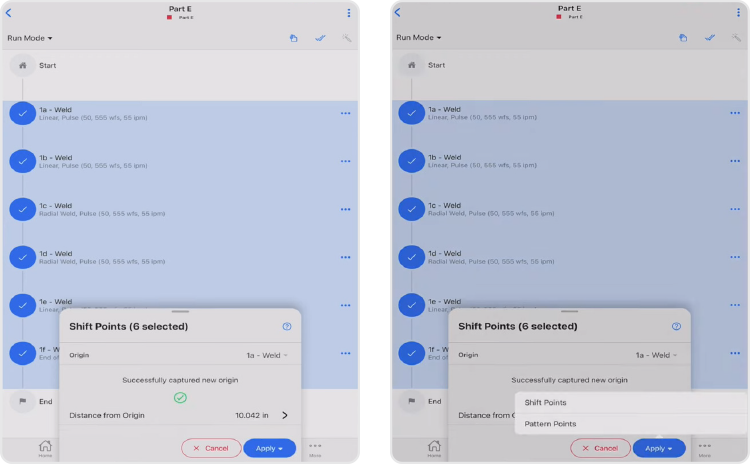

6. Edit and Shift Welds: Adjust and move welds as required.

7. Pattern Welds: Duplicate weld patterns for similar tasks.

8. Real-time Monitoring: Benefit from cloud connectivity to monitor your welding data in real-time.

9. In-App Support: Access support directly within the app whenever you need it.

For more detailed instructions and insights, you can visit our guide on How to Program a Robotic Welder.

Easy Transfer and Sharing of Programming

The Beacon app enhances flexibility in programming and sharing across different systems and locations:

- Wireless tablet control: The app runs on your usual tablet that allows you to walk around and program parts on different systems easily.

- Copy and share between systems: You can copy programming from one part to another, facilitating the sharing of welding procedures and parts across multiple locations.

- Controlled access: The software gives you full control over who can share and access these procedures and parts. This is particularly beneficial for businesses with operations spread across various sites, ensuring consistency and quality in welding practices.

Beacon not only simplifies the programming process but also adds a layer of security and convenience, making it an ideal choice for shop owners looking to optimize their welding operations.

The simplicity of Beacon can transform your welding processes without hiring more welders or programmers.

Beacon Care - Comprehensive Support for Your Cobot

Hirebotics has introduced Beacon Care, a program that echoes the concept of Apple Care but is specifically tailored for your robotic welding system. This service provides full coverage for any issues that might arise, ensuring your operations stay up and running smoothly. Here's what Beacon Care offers:

- Shared cost for repairs: In case of any malfunction, the repair costs are shared between Hirebotics and you, the shop owner.

- Loaner equipment availability: To minimize downtime, if your equipment needs repair, Hirebotics provides loaner equipment to keep your operations uninterrupted.

- Maximized uptime: The primary focus is on maintaining maximum uptime. In the event of a mishap or accidental damage, the goal is to ensure your shop isn’t left idle for extended periods while repairs are underway.

The Impact on Welding Automation

For welding shops, Beacon is a huge step forward in many ways. This app enables welders to program cobots themselves, reducing the reliance on specialized robot programmers and enhancing the productivity and quality of welding jobs.

Shops can take on more jobs and improve their time-to-market, all while ensuring a high level of quality. Our cobot welders are known for easy setup and ability to handle consistent, repeatable welding tasks, freeing your skilled welders for other important tasks.

A Teach Pendant vs Beacon Comparison

| Feature | Teach Pendant | Beacon Software |

| User Interface | Complex, requires training | Intuitive, easy to use |

| Programming Knowledge | Traditional robotic systems can take weeks or more to learn | Welders with no programming knowledge can begin using it easily |

| Flexibility | Limited; requires an expert for changes | High; easy to adapt and modify |

| Mobility | Limited to robot location | Accessible remotely via cloud |

| Real-Time Monitoring | Limited capabilities | Comprehensive monitoring and alerts |

Beacon: Easy to Implement and Scale

As a welding shop owner or manufacturer, you're always looking for ways to streamline operations. That's why Hirebotics' Beacon app is so valuable.

It offers a modern, user-friendly alternative to traditional teach pendants, aligning well with the needs of contemporary manufacturing environments.

These 3 real-world case studies showcase just how easy and valuable cobots can be to your shop.

With Beacon, the need for extensive programming knowledge is greatly reduced, making it easier for you and your team to manage automation processes.

This translates into less training time and costs, allowing for a more streamlined operation and better ROI for your business without hiring more staff.

Ready to take your welding shop to the next level with Beacon? Schedule a demo and see how we can help you integrate automation into your operations efficiently, effectively, and securely.