A Guide to Advanced Welding and Advanced Welding Tools

September 20, 2021

It’s no denying welding is an exciting and dynamic industry. It’s never dull. Once you’ve mastered manual welding and want to excel in the field, learn advanced welding. Advanced welding includes a thorough understanding of the different welding types and technologies.

Do you want to explore the nature of advanced welding? What are the tools and equipment used?

In this article, we will discuss:

- What is Advanced Welding?

- What are the General Types of Advanced Welding?

Mechanized Welding

Semiautomatic Welding

Automatic Welding

Robotic Welding - What are Examples of Advanced Welding Tools?

Mechanized welding Tools

Semiautomatic welding Tools

Automatic welding Tools

Robotic Welding Tools

What is Advanced Welding?

In addition to the skills of basic manual welding, advanced welding uses modern technology in fabrication. This modern technology can mean adding machines and tools to the mix.

Welders who are trained in this area have advanced technical and welding skills.

General Types of Advanced Welding

There are a few general types of advanced welding, and sometimes the different processes can fall into one or more of these categories.

But let’s start by discussing four types of advanced welding.

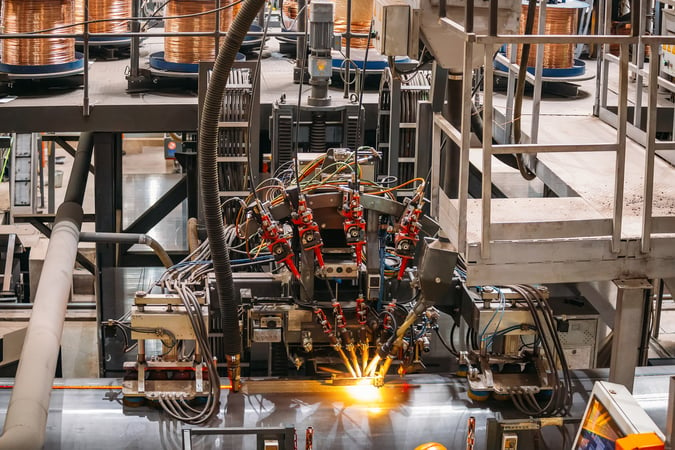

Mechanized Welding

Mechanized welding is done with the help of mechanical/electrical welding tools. In this type of welding, the machine holds the gun, torch, or electrode.

Mechanized welding reproduces high-quality welds with minimal operator interruption. But, the welder needs to make manual adjustments to the machine during the process to maintain the required welding positions.

Semiautomatic Welding

Semiautomatic welding is welding manually with the help of a machine that automatically controls one or more of the welding conditions.

For example, the welder holds the torch while a machine feeds the electrode automatically to the arc. Gas Metal Arc Welding (GMAW/MIG) and Flux Core Arc Welding (FCAW) are welding processes that can benefit from semi-automation.

GMAW is arc welding using a metal electrode. FCAW is also a type of arc welding but uses a flux-cored electrode.

Automatic Welding

Automatic welding is a fabrication with the use of a welding machine. This type of advanced welding only needs occasional to no observation of the welding process from the welder. Once set, there’s no need to adjust the equipment. However, If the need arises, adjustments can only be made at the beginning of the weld and not during the welding process. Submerged Arc Welding and Electron Beam Welding are examples of automatic welding.

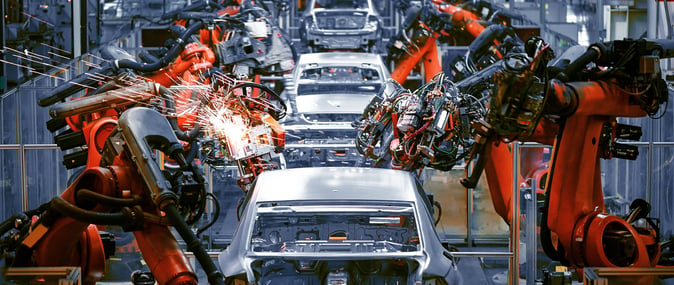

Robotic Welding

Robotic welding is a type of automatic welding in which a robotic arm is programmed to do the welding. Once set up, there’s little need for any input from the welder.

There are different types of robotic welders - one is the industrial welding robot, commonly used by the automotive industry. The other variety of robotic welders are collaborative robots or cobots. These are robotic arms that are built to work alongside humans.

Advanced Welding Tools

There are many different kinds of advanced welding tools and equipment. With technology, new ones come out all the time. In this article, we will discuss a few examples for each type. These tools include welding tool kits, welding inspection tools, and welding accessories.

Mechanized Welding Tools

Pipe Mechanized Welding System

This is a type of mechanized welding system that adds motorized automation to pipe welding.

Flat Track

A flat track helps in the secure mounting of a weld head to a column and boom manipulator. They commonly use this as a travel carriage for complex automation systems when welding long seams. They also use it to attach a weld head to a cart or wall for storage. The flat track comes in different sizes and can be fitted with magnetic shoes for a more secure hold.

Mechanized Wire Feeder

A mechanized wire feeder delivers the electrode to the welding machine. There are many types in the market, but usually, they are lightweight and offer high torque output. It also has speed control and the ability to control the roll tension and feeder placement. It usually has flexible drive rolls for different types of wires.

Semiautomatic Welding Tools

Welding Manipulator

A welding manipulator can be best described as an extra arm that helps you in your welding process. The welding equipment is installed on the arm. They use the welding manipulator to reach difficult places during welding. Welding manipulators have safety features and are adjustable so you can move them around.

Welder Positioner

A welder positioner is a device that holds, moves, and rotates the welded parts.

Automatic Welding Tools

Automatic Welding Lathe

Automatic lathes are usually used for the tube to tube welding. This machine adapts to different lengths, thicknesses, and types of tubes and pipes. Some companies offer it as a modular concept.

Video Monitoring System

Video monitoring systems enable the operators to keep an eye on what’s going on. These systems are beneficial for closed weldings like Submerged Arc Welding and Electron Beam welding.

Seam Tracker Kit

A seam tracker is one of the new technologies in automatic welding(for now). It’s a system that measures the exact location of the seam and corrects the position of the welding machine, so it follows the seam. These systems have mechanical sensors that correct the path if the seam is not in the proper position.

Robotic Welding Tools

Industrial welding robots

An industrial welding robot is a robotic arm that you can usually find in the automotive industry. It’s big and bulky and works best in high-volume welding production. It needs to be programmed by a robotics specialist. This type of welding robot is dangerous when humans come in contact with it. Because of safety issues, it’s usually housed in cages.

Collaborative Robots Welding

Collaborative robots or cobots are robotic arms that are built to work alongside humans. Cobots work best for businesses that have low volume, high-mix environments. If you have a welding business, cobots are a great way to automate it.

Unlike industrial robots, they are easier to program. If we’re talking about programming, the Cobot Welder from Hirebotics is the easiest cobot to set up in the market. All you need to do is download an app to your smartphone or tablet.

Your welders can learn to program the cobot welders in 20 minutes or less.

And less downtime means faster ROI for your business.

Final Thoughts

Welding is a critical construction activity that requires proper attention. With advanced tools, especially robotic ones, we can cut the risk factors and increase productivity.

There are so many more things to learn about welding than what we have discussed here. But we hope that this article will be a good starting point to begin your journey in advanced welding.