7 Hidden ROI Drivers of Cobots

May 29, 2025

Most fabricators considering welding & plasma cutting automation start with one question: How much will we save on labor?

It’s a fair place to begin, but it's just the tip of the iceberg. Modern cobot welding and cutting systems unlock value far beyond headcount reductions.

In this post, we’ll walk through seven often-overlooked sources of ROI that can make collaborative welding and plasma cutting systems a high-impact investment across your operation.

1. Higher Throughput Without Adding Headcount

Welding and plasma cutting cobots help you scale production without hiring additional skilled welders—a game-changer in today’s labor market.

Some manufacturers report up to 400% increases in throughput, allowing them to take on larger orders and grow revenue with existing staff.

2. Quality That’s Consistent and Repeatable

Defects and rework eat into profits. Cobot Welder and Cobot Cutter deliver high-quality, repeatable welds every time—reducing scrap, returns, and warranty issues while improving customer satisfaction.

3. Safer Work Environment = Lower Risk

By offloading dangerous, repetitive welds and cuts to cobots, companies reduce exposure to arc flash, toxic fumes, and repetitive strain injuries—cutting down on workplace injuries and associated costs.

4. Stability in a Volatile Market

Cobot Welder and Cobot Cutter help manufacturers navigate economic uncertainty. They enable predictable costs and consistent output, even when labor markets or supply chains are in flux.

5. Empowered Workforce and Higher Morale

Rather than replacing workers, welding and cutting cobots elevate them. They allow welders to transition into safer, more engaging roles — improving retention and reducing turnover.

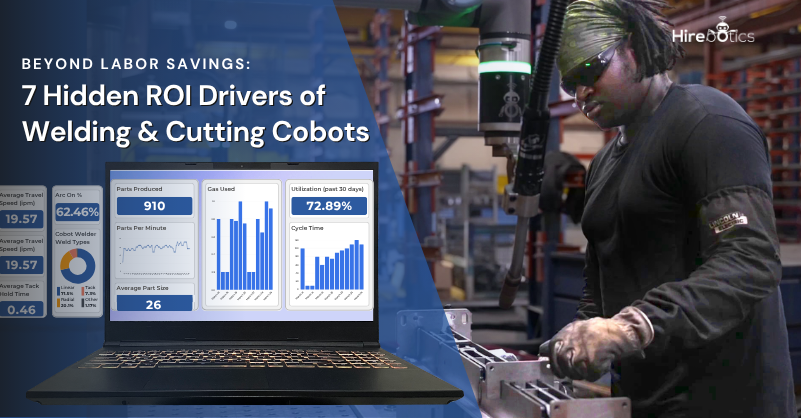

6. Smarter Decision-Making Through Data

Modern welding and plasma cutting cobots come with built-in data collection and visualization tools. From arc-on time to cycle efficiency, these insights support continuous improvement and smarter business decisions.

7. Faster Delivery, Better Reputation

Welding and plasma cutting cobots reduce bottlenecks and help you hit deadlines more reliably. That means happier customers, more repeat business, and a stronger competitive edge.

If you’re only looking at labor savings, you’re missing the big picture. Welding and plasma cutting cobots deliver ROI across your operation—from safety and quality to scalability and resilience.

Ready to unlock the full potential?