Why Automated Weld Fixturing Reduces Rework

January 13, 2026

The Hidden Cost of Manual Setup

Rework eats into fabrication shop revenue, with inconsistent part positioning being a primary culprit. When parts shift between setup, every subsequent weld operates on incorrect geometry. The welder's skill becomes irrelevant—the foundation is wrong before the arc strikes.

Manual fixturing introduces variation at every step. Clamp pressure varies between operators. Reference edges shift slightly. A part that was square yesterday sits slightly off today. These micro-variations compound across production runs, creating the conditions for costly rework.

How Automated Fixturing Eliminates Positional Variance

Automated weld fixturing systems use pneumatic or servo-driven clamps with consistent pressure and positioning. Every part loads to exactly the same reference points. The system applies identical clamping force every cycle. This eliminates the primary source of weld defects: parts moving during the weld sequence or being positioned incorrectly from the start.

This consistency can be applied both basic and complex part geometries. When a collaborative welding robot returns to the same location for a second or third pass, the part must be exactly where the system expects it. Automated fixturing ensures this repeatability—well within tolerances for structural welds.

Data Center Fabrication: Where Fixturing Pays Immediate Dividends

Data center infrastructure projects demand volume and consistency simultaneously. Racks, cable trays, structural supports, and enclosures require identical welds across hundreds or thousands of units. A single rack might need dozens of welds, all meeting the same specification.

For shops serving the data center market—projected to grow from $241B in 2024 to $456B by 2030—automated fixturing becomes an essential way to ensure repeatability. The alternative is manual setup for every part, which introduces the variation that leads to rework, delays, and margin erosion.

Consider a typical high-volume data center production run: hundreds of identical parts, each requiring multiple welds. Even a small percentage reduction in rework translates directly to labor hours saved, delivery timelines met, and quality issues avoided. Manual fixturing might require addressing defects on a meaningful portion of parts. Automated fixturing can reduce that dramatically.

The recovered hours translate directly to capacity gains—shops can meet delivery schedules without adding welders, addressing the ongoing skilled welder shortage while meeting surging demand. Equally important: identical, consistent welds make costs predictable rather than estimated. When every weld executes the same way, shops can calculate exact cost per foot of weld instead of building in buffers for variation and rework.

Fixture Design That Speeds Cobot Weld Cycles

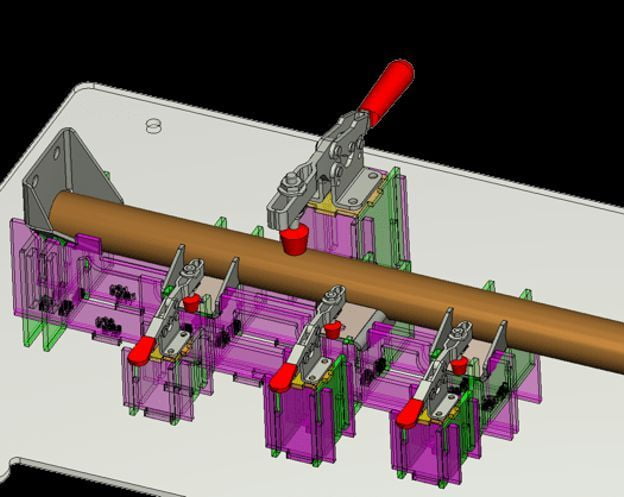

Effective fixture design for collaborative welding robots considers three factors: part accessibility, cycle time reduction, and operator ergonomics.

Part Accessibility: Fixtures must provide clear torch access to all joint locations without requiring robot path modifications. Poor fixture design forces longer torch travel distances or awkward approach angles that slow cycle times and increase program complexity.

Quick-Change Interfaces: Shops running multiple part types benefit from modular fixturing with quick-change baseplates. A quick fixture swap beats extended manual setup adjustments for different part geometries.

Consistent Work Height: Positioning all fixtures at the same work height allows one robot program to serve multiple stations. The robot doesn't need height compensation—it moves between fixtures knowing exactly where each weld joint sits in three-dimensional space.

The Role of Through-Arc Seam Tracking

Even with excellent fixturing, raw material variation creates minor edge inconsistencies. Mill tolerances, thermal cutting distortion, and plasma edge quality all introduce small deviations from nominal part geometry.

Through-arc seam tracking uses weld current feedback to detect the actual weld joint location in real-time. The robot adjusts its path during welding to follow the actual seam rather than the programmed theoretical location. This compensates for the fixture's job of holding parts in position while accounting for material reality.

The combination of automated fixturing and seam tracking creates a system where:

- Fixturing eliminates gross positional errors

- Seam tracking compensates for material variation

- Rework drops to minimal levels

Practical Implementation: What Shops Actually Need

Implementing automated fixturing doesn't require custom engineering for every part. Effective approaches include:

Modular Clamping Systems: Grid plates with standardized mounting holes accept different clamp configurations. Modular systems can handle dozens of part geometries with quick fixture change times.

Pneumatic Actuation: Shop air powers automated clamps. No hydraulics, no complex controls—just consistent clamping force every cycle.

Integration with Cobot Systems: Collaborative welding platforms like Hirebotics Beacon include fixture control interfaces. The robot program triggers clamp actuation, ensuring parts are secured before welding begins. At $100 per month per robot, the Beacon platform provides the cloud-connected intelligence needed for digital traceability alongside fixture coordination.

Measuring the Rework Reduction

Shops implementing automated fixturing with collaborative welding systems consistently see rework rates decline significantly. Setup times drop for repeat parts. The distinction between "good days" and "problem days" on the production floor diminishes—consistency becomes the baseline rather than the exception.

The economics are straightforward: fewer rework hours mean more productive welding hours. Consistent welds also enable accurate cost calculations—shops can calculate exact cost per foot of weld and per cycle time instead of estimating with contingency buffers. For data center fabricators managing high-volume production schedules, this translates to capacity gains without adding welders—addressing the skilled welder shortage while meeting surging demand.

Fixturing as Production Infrastructure

Automated weld fixturing isn't an accessory to collaborative welding—it's foundational infrastructure that determines whether the system delivers consistent results or requires constant intervention. For shops positioning themselves to capture data center fabrication opportunities, fixturing investments pay returns through reduced rework, faster cycle times, and the production consistency that repeat customers demand.

The cost of poor fixturing appears in rework labor, delayed deliveries, and margin erosion—expenses that quickly dwarf the cost of proper fixturing itself. The value appears in first-pass quality, predictable cycle times, and the ability to commit to volume production schedules with confidence.