Keep your employees, Fire your robots!

September 3, 2019

Catchy headlines in the news today would make you believe that robots are stealing jobs. Fear sells.

For more than a century technological innovations have changed the nature of work: from the cotton gin to the power loom, the typewriter to the personal computer, the mechanical reaper to the combine harvester. The result of innovation is a more abundant food supply, higher standards of living globally, lower cost products (in real dollars). But the fact remains that great technological achievements cause short-term uncertainty for the people and workers closest to the change. And uncertainty leads to fear.

A significant impediment to adopting robotic automation is the impact it has on long-time employees. When business is robust, it is easier to explain to your employees that your new robot will not be stealing anyone’s job. You may say something like “We’ve made this investment in automation to meet the demands of our business in the coming years.”

But your employees have seen this story before — when times are good, the company invests in new equipment. But if business slows, it’s the employees that are laid off. The machine / robot / you-name-it-piece-of-equipment has a permanent home in the factory but not the long-tenured employees that helped build your business.

Worsening Labor Shortage in Manufacturing

According to the Bureau of Labor Statistics, unemployment in the manufacturing sector of the US economy is only 3.0% (as of July 2019), which is significantly better (or worse, depending on whether you‘re the employee or employer) than the general economy, where unemployment is only 4.0% (as of July 2019). Worse yet, the unemployment rate within manufacturing is at a 20 year low.

While this is great for employees, it is a significant challenge for manufacturing companies. The record number of job openings within manufacturing translates into workforce turnover and unfilled jobs. It’s hard to meet customer deliveries when a manufacturer is uncertain about who will show up on any given day.

Three Options for Manufacturers Facing Labor Shortages

In our time working with manufacturers across the country, we have witnessed a number of options that companies use to solve their labor shortage challenges. We’ll go through a few of the most common, including some really creative experiments! If you have seen other techniques to address the labor shortage, leave them in the comments below.

Increase starting wages, increase recruiting efforts

This is the most obvious and most widely used, so we won’t belabor it. In tight labor markets companies routinely increase starting wages and/or shift premiums to attract talented individuals. There’s no dispute that people should be paid based on the value they bring to an organization and we wholeheartedly support competitive wages in manufacturing.

But the game of increasing pay when facing labor shortages can have a few unintended consequences:

- Wage wars with nearby companies

- Higher cost basis if/when the economy slows

Wage wars with neighboring companies

In tight labor markets it can be common to increase starting wages to attract local talent. This works for a short period of time until another local manufacturer fighting for the same talent raises their starting wages, too. Great for employees looking for a bump in pay — who doesn’t want that!?

But there comes a point at which your company gets exhausted with the resulting turnover and retraining and you find that your company really didn’t get ahead. The labor shortage has turned into a tug-a-war with another local company or companies. And sometimes, you end up causing more turnover of seasoned employees instead of growing your workforce as originally planned.

Higher cost basis if/when the economy slows

No one likes to talk about an economic downturn or natural business cycles, but it’s a reality that if you want to survive for the long term you must plan for it. When a business gets caught up in wage wars and the eventual economic correction happens, you will be forced to reduce costs, your business and you might have to let more employees go because of increase in fixed employee costs during your recent hiring spree.

No one wants to layoff employees and no employee wants to be laid off. It’s a terrible and often life changing event that should be avoided at all costs. Good planning can help.

So what’s a company to do in a strong economy when faced with labor shortages and a local manufacturer just increased their starting wages?

- Consider spending the equivalent money on performance bonuses based on hitting company profitability targets, project milestones, and/or customer satisfaction scores.

- Offer training and job advancement with commensurate pay increases for the employees new skill and value to the organization.

- Make improvements to the work environment that employees clearly see and benefit from — air conditioning in the shop, better break room facilities, and so on.

Invest in Automation

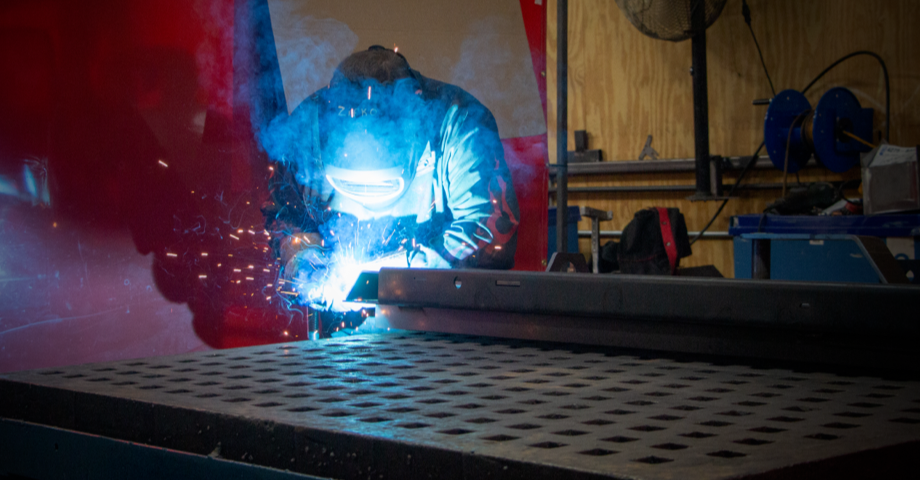

For decades manufacturing companies have invested in automation for various reasons: (1) keep employees away from dangerous machines or environments, (2) improve consistency of a difficult process, and (3) increase throughput in highly repeatable tasks.

Manufacturers also look at making capital investment into automation and robotics when they struggle to find talented employees. This can pose a few additional risks that might not be apparent during the early phases of a project, specifically time to achieve a return and what to do when the business cycle turns.

Automation projects typically appear straightforward at first glance. Pick this up, put it there. Wait for this, then do that. But the complexities quickly set in when the project is underway.... inconsistent presentation, integration issues, programming challenges, and so on. We have seen “simple” projects attempted by large and small companies take more than six months of work and only then realizing that the task is not a good candidate for automation.

But your company is different. You did, in fact, successfully implement your automation or robotics project. Excellent! Now, what happens if and when the business cycle turns and orders slow? The capital investment can seem like a boat anchor. Companies scramble for cost savings and often turn to employees, viewing employees as variable costs, and lay them off. The robots keep running because the investment is a sunk cost.

Hire a robot!

Say what?! Hire a robot? What does that even mean? Let’s break it down to see where this option fits in.

More popularly known as Robots-as-a-Service (RaaS), the concept has been around for several years and was pioneered by Hirebotics. The idea is simple. Most manufacturing companies do not need to be experts in robotics no more than they need to be experts in software or IT security, which is typically left to experts. Instead, companies pay for automation based on the usage of the equipment.

There are a few key features that you should be aware of when considering hiring robots to address your labor shortage.

First, the notion of hiring a robot is that you do not own the asset. That has pluses and minuses and you should carefully consider the trade-offs for your business. Not owning the asset means that it’s not yours to fix or repair. It’s up to your automation partner. On the flip side, not owning the asset means that you will continue to pay for it while you use it. When the asset is no longer needed, you can return it. This is no different than forklifts, which most manufacturers rent (who owns a forklift anymore!?).

Hiring a robot should be just like hiring a human employee, you should have the ability to scale it up and down as needed. If a company is disguising a financing solution for their equipment as “robots-as-a-service” they might be offering a way to scale up as your business needs, but not scale down. Often times these deals are long lived with no easy way out when business slows.

Robots-as-a-service, as the name implies, must include service. That means that when your company needs help with the equipment or help with the application, you can get service quickly and it’s included in the rate you’re already paying.

Finally, and partially touched on above, the most appealing feature of hiring a robot is the ability to scale your business up and down as you need. When you take on a new project and you face a labor shortage or perhaps a short term need, you can hire a few more robots to work with your employees and deliver to your customer. When the project is complete and the additional robots are no longer needed, fire the robots instead of your employees. Your employees will view the equipment as a tool to help the company instead of seeing robots as job killers. They’ll welcome the equipment when they know it’s temporary and they are permanent.